A Step-by-Step Look at the Art Behind the Glass

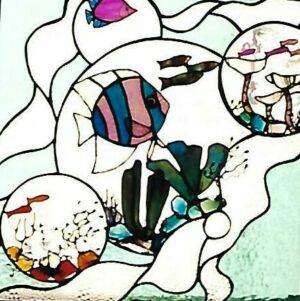

When the warm glow of sunlight passes through a stained glass suncatcher, it can feel effortless — just memories and daydreams caught in light and color, quietly brightening a corner of your window. This is why many people are drawn to suncatchers. What you don’t see are the many careful steps, tools, and decisions behind that moment.

Every stained glass suncatcher begins long before the glass is ever cut. Each one carries hours of hands-on work, patience, and experience that simply can’t be rushed.

Traditional stained glass suncatchers are very different from decorative pieces made from acrylic, resin, or pre-cut kits. They are built piece by piece using real art glass, hand tools, and time-tested techniques that have been passed down from generation to generation since the Middle Ages.

The glass I use is made using traditional processes by companies like the Paul Wissmach Glass Factory, which has been making art glass for over 120 years.

This difference in process is also why handmade stained glass suncatchers often cost more than mass-produced alternatives. To understand why, it helps to look at what actually goes into making one. While others may have their own ways, this is how I do it.

The Stained Glass Suncatcher Process

A step-by-step look at what really goes into each piece

1. Researching Ideas and Themes

Long before any glass is cut, time is spent deciding what to make.

This stage involves researching themes, images, and styles that people naturally connect with — designs that feel welcoming in a home and work beautifully with light. Not every idea translates well into stained glass, so careful thought is given to visual appeal, structural integrity, and how the finished piece will function when hung in a window.

Although this work happens behind the scenes, it shapes everything that follows.

2. Designing and Preparing the Pattern

Once an idea is chosen, it’s turned into a workable stained glass pattern.

The design is drawn, refined, traced onto pattern paper, and then carefully cut apart. Every line must serve a purpose — supporting the glass, guiding the eye, and allowing the piece to hold together safely over time.

Patterns are rarely finalized on the first try. Many are adjusted multiple times before they’re ready to become glass.

3. Selecting the Glass

Choosing glass is about far more than color.

Art glass varies widely in texture, transparency, and movement. Each sheet behaves differently when cut and reacts uniquely to light. Even two pieces taken from the same sheet can look completely different once hung in a window.

When I select glass, I look at color and texture, how each piece works together to support the theme, and how it should make you feel when you see it. Will it spark something inside you?

4. Cutting and Precision Grinding

Each pattern piece is cut by hand from the selected glass.

Glass cutting requires a controlled score and a careful break. Curves, fine details, and narrow sections take experience to cut cleanly. After cutting, every piece is ground to precise tolerances so it fits exactly as intended.

This step is especially critical when lead came is used. Narrow U-channel lead leaves very little margin for error — grinding must be extremely accurate so the glass doesn’t show beyond the lead lines. Each piece is inspected before moving on.

5. Foil, Lead Came, and Structural Choices

Depending on the design, pieces are either wrapped in copper foil or fitted into narrow lead came.

Copper foil allows for fine solder lines and detailed designs, while lead came provides structure and a classic look — but demands tight tolerances and careful fitting. Many suncatchers use a combination of both methods.

Every piece is prepared by hand, burnished, and checked for consistency before assembly begins.

6. Creating Decorative Details and Overlays

Some designs include additional hand-built details that go beyond basic assembly.

Foil overlays are laid directly onto the glass, trimmed to shape, and burnished in place before soldering. Decorative elements made from tinned copper wire are also formed by hand — wire is straightened, sometimes twisted, cut to length, bent into shape, and attached piece by piece.

These details add depth, texture, and character, but they also add time and complexity to the process.

7. Assembly and Soldering

With all pieces prepared, the suncatcher is assembled using the original pattern as a guide.

Solder is applied to every seam to permanently bond the piece together. Heat, timing, and consistency all matter. Structural strength and clean visual lines depend on careful, steady work.

Inspection continues throughout assembly to ensure balance, strength, and accuracy.

8. Cleaning, Patina, and Finishing

After soldering, the piece is thoroughly cleaned and dried.

Patina is applied to darken or enhance the solder lines, and this step must be done carefully and at the right pace. If patina overreacts, it can affect both the metal and the glass. The piece is then rinsed twice to ensure no residue remains that could cause corrosion.

Once dry, a protective polish is applied. This polish must cure overnight before it’s brushed off and buffed by hand.

9. Final Inspection and Completion

Final inspection happens only after polishing is complete.

The piece is checked for strength, balance, clean lines, and overall finish. Hanging hardware is inspected to ensure the suncatcher will hang safely without placing stress on the glass.

Only after passing inspection at every stage — from cutting and grinding to soldering, patina, and polish — is the piece considered finished.

Why This Process Matters

This entire process takes hours, often spread over multiple days. Every step builds on the one before it.

That time, care, and experience are what allow traditional stained glass suncatchers to become long-lasting heirlooms — fond memories filled with light, handed down through the years. It’s also where the difference between handmade stained glass and mass-produced decorative pieces becomes clear.

Thanks for taking a closer look at the art behind the glass.

Until next time, keep your spirit light — look out your window and daydream.